Mold laser welding machine 400W mould Laser Welders CE dapenglaser

Mold laser welding machine 400W mould Laser Welders CE dapenglaser

Features:

1. Processing speed is fast;

2. Small thermal deformation and heat affected zone (suitable for processing high melting point, high hardness, special materials)

3. Local heat treatment of the parts;

4. It can process complex shapes of parts and small parts, and can also process in vacuum;

5. No noise, no pollution to the environment;

6. Combine with computer technology to facilitate automation;

7. Improved existing product structure and materials due to advanced processing methods

8. Can improve the quality of the workpiece.

9. No pre-heat treatment is required, and the workpiece will not anneal after welding;

10. Deformation-free collapse;

11. No pores and trachoma;

12. Can be used for cracks, collapses, corners, sand holes and repairs after use of the mold;

13. Different hardness hardness materials (such as: HRC60) can be obtained by using materials with different hardnesses. The toughness of the cold die and the cutting edge of the cutter can also be repaired, which eliminates the complicated preheating and heat preservation processes of ordinary argon welding.

Application:

Mold industry

1. Injection mold 2, stamping die 3 die-casting die 4 rubber die 5 copper alloy die

Foundry industry

This welder also has a good performance in casting defects. Quick and precise repair of the pores, slag holes, shrinkage holes, etc. during the casting process.

It has excellent repair effect on defects such as ductile iron, gray iron and stainless steel, and has fast welding repair speed, no color difference or small color difference after welding, and is suitable for the production of factory scale.

Various workpiece parts repair industry

This machine can perfectly repair shafts, teeth and other workpieces.

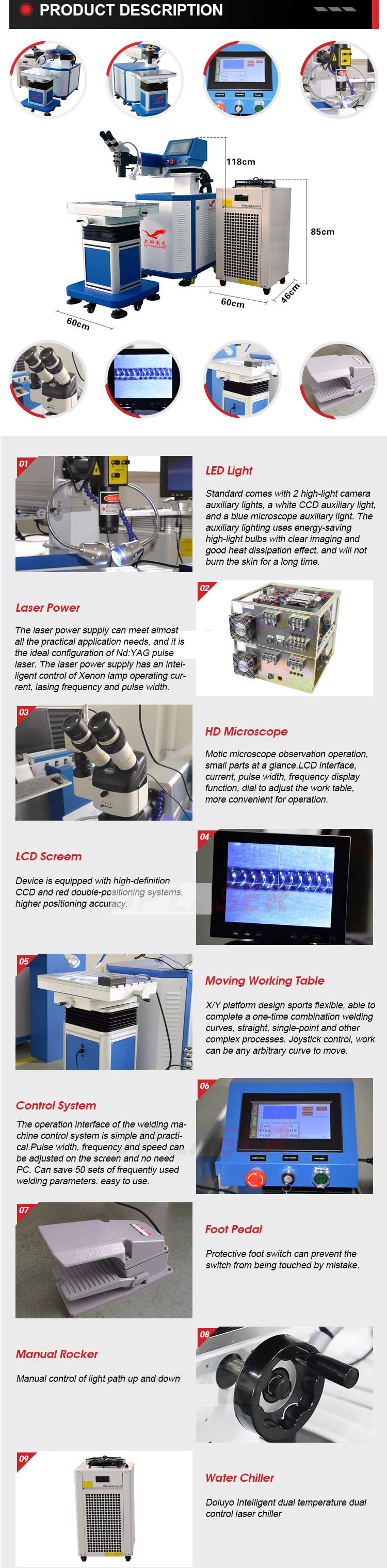

Technology parameters

| Model | DPH-200 | DPH-400 |

| Maximum laser power | 200W | 400W |

| Welding depth | 0.1-1.5mm | 0.1-2.5mm |

| Welding wire |

0.4mm (0.6mm weld slower, 0.8mm can’t use) |

0.4mm, 0.6mm (0.8mm weld slower) |

| Power requirement | 220V | 380V |

| Pulse frequency | 1-20Hz | |

| Rated Power | 10KW | |

| Laser work material | Nd:YAG | |

| Focus lens | 100-150mm | |

| Laser wavelength | 1064nm | |

| Minimum spot size | 0.2mm | |

| Pulse width | 0.1-20ms | |

| Observation system | Cross microscope | |

| Cooling mode | Water cooling | |

| Working table | 400×300mm | |

| Movement workbench | XY Manual, Z electric lift 300*200*300mm | |

| Frame | Aluminum alloy | |

| Dimension | Machine: 150*60*118cm Chiller:60*46*85cm | |

| Consumables | Xenon lamp, protective lens (Recommend buy two more units) | |