Why Laser Marking/Engraving? Enhances the aesthetical & monetary value of products, product tracking & identification. 1. High Beam Quality; 2. Low Consumption; 3. Maintenance Free

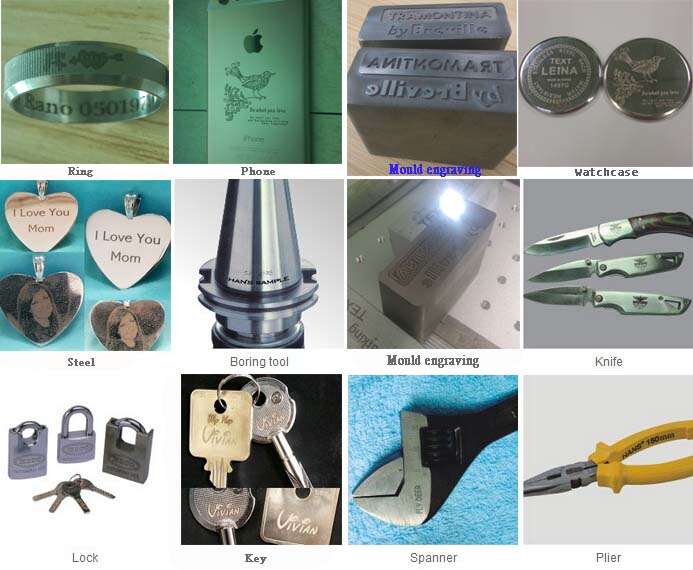

Metal Industry, Jewelry Factories, Hardware Tools, Electronics Components, Auto Parts, Mobile & Accessories, Clock&Watches, Planting Coating Materials, Spray Material, Plastic, Rubber, Spectacles,Jewelry engraving,etc.

Specification:

|

Laser wavelength |

1064nm |

|

Power adjustment range |

10-100% |

|

Repetition frequency |

20-80KHz |

|

Output beam quality |

M2:1.2~1.8 |

|

Marking linear depth |

0.01-0.2mm |

|

Min. Spot diameter |

0.01mm |

|

Min. Character size |

0.1mm |

|

Repetition accuracy |

±0.02mm |

|

Max. Liner marking speed |

7000mm/s |

|

Standard marking area |

100*100mm or 150*150mm |

|

Power consumed |

500W |

|

Electrical demand |

Ac220V±10%.50HZ.10Amp |

|

Software |

EZCAD |

|

Cooling mode |

Air-cooling |

|

Operational Temp Range |

10-40℃ |

|

Machine Size & Weight |

Desktop: 800*600*1420mm 120Kg |

Software: EZCAD

|

True Type Fonts |

Single Stroke Fonts |

Elliptical Text |

|

Sequential Serial Numbers |

Customizable Auto Dating |

Barcodes |

|

QR Codes and Data Matrix |

UID Wizard |

Logos |

|

Images - JPG, TIF, GIF |

CorelDraw, Adobe Illustrator |

Raster Graphics |

|

Vector Graphics |

CAD Files |

|

Materials:

|

Stainless Steel |

Steel |

Aluminum, Carbide |

|

Nickel |

Titanium |

Cast Iron |

|

Chrome |

Painted Metal Alloys |

Multi-Coated Metals |

|

Plastics/Rubber |

Backlit Buttons |

Polycarbonate |

|

PVC |

Composites |

Many more materials |